Power Tools

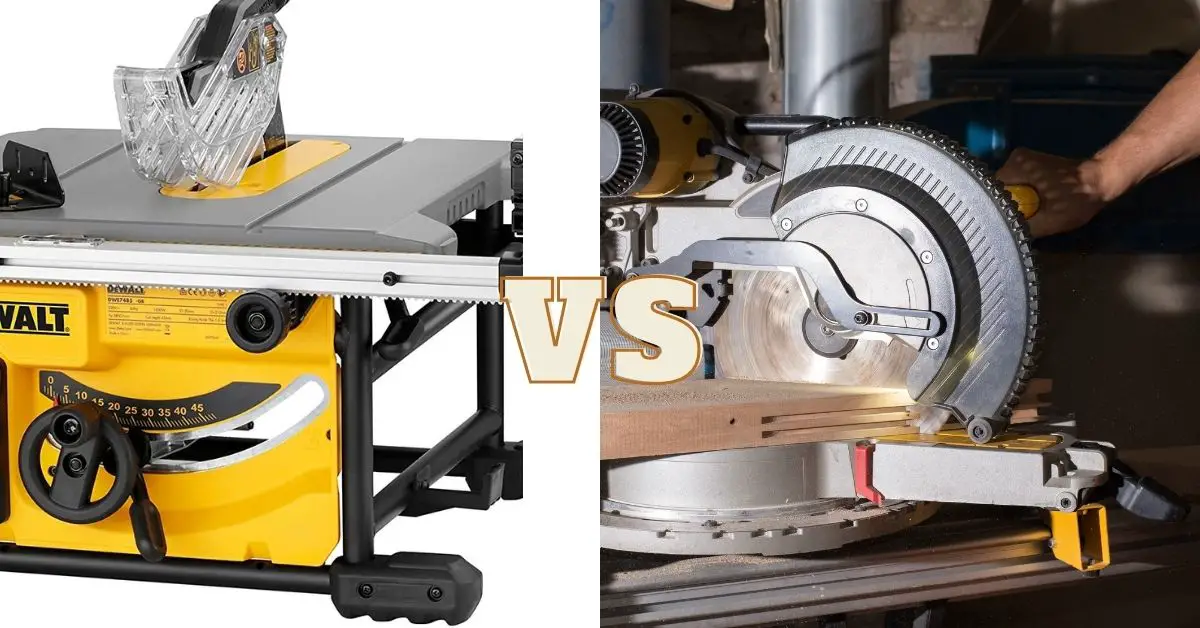

Chop Saw vs Table Saw

If you work at a construction site or are responsible for various construction tasks or installations, there are high chances you have a workshop or a garage full of power tools for DIY projects or quick fixes. As you assume more challenging tasks and projects where you'll require more accuracy when cutting plastic, metal, and wood, you will need both the table saw, and chop saw.

While these two tools are handy in the workshop, they are quite different. Here, we compare the table saw and chop saw and see which one is best for you.

Read on to find out!

Chop saw

What is a chop saw?

Chop saws are often mistaken for miter saws. While they do look the same, chop saws are larger, and they use a blade of a minimum of 14 inches and can only make straight cuts. They are not designed for precision and are mostly utilized for cutting very tough materials.

Chop saws come in two different types; TCT and abrasive saws. These two saws work to ensure that you can cut through the hardest materials through their substantial cutting power. Again, they look a lot like the miter saw since they both feature handles and guards when it comes to appearance.

Types of chop saws

Abrasive chop saw

The abrasive chop saw is at times called the bacon slicer, and it utilizes a huge and abrasive blade to cut through even the toughest metal. It is normally made using grit, strengthening fiber, and resins, which is why it cuts through metal like a hot knife through butter.

While it is impeccably built and efficiently designed, this chop saw has various shortcomings. First, the most prevalent downside is the cutting speed. Typically, abrasive cutting blades will cut through almost any material, though they are somewhat slow compared to the TCT blade.

The disc is designed such that the more you cut using it, the more the blade's diameter reduces. In the long run, it will result in a significant decrease in the cutting capacity of this power tool.

Abrasive Chop Saw Pros and Cons

Pros:

Cons:

Conclusion:

Again, this machine sparks when cutting, so you might need hot works depending on your worksite. Regardless of the blade drop-down being designed to make straight cuts, you can modify the clamp at the base to make 450 cuts.

TCT chop saw

For a long time, the thought of a TCT chop saw being used to cut steel would have been terrifying for the workshop owners and worksite supervisors.

The TCT is the only chop saw featuring baring teeth and is precisely designed to cut steel. Previously they were made using HSS and utilized on reduced RPM, cooled cold saws. After some time, this changed when a group of manufacturers managed to create a machine that functioned at increased RPM and sported TCT blades.

TCT Chop Saw Pros and Cons

Pros:

Cons:

Conclusion:

No lubrication is required because of the high-temperature impervious carbide teeth, thus the dry-cut phrase.

Chop saw accessories

A functional mobile cutting table comes in handy in lessening noise and limiting dust, burrs, and sparks, thus offering a safe working space.

Table saw

What is a table saw?

A table saw is a saw that's affixed beneath the surface of a table, with a section of the blade projecting on top of the table, where it's visible and used to cut wood. The projecting section makes it a consistent cutting tool that allows you to feed cutting material to the blade in a precise, controlled, and measured manner.

Moreover, the table part features different ways to measure your cuts and set various angles. The compilation of the saw is affixed on an arbor, which holds it in place, and lets you alter the cutting angles and depths. The table comes in handy when feeding the material to the blade and making clean and accurate cuts. .

Table saw Pros and Cons

Pros:

Cons:

Conclusion:

While a table saw has a very simple look, it has a myriad of uses for woodworking. What’s more, it offers substantial consistency and convenience. This power tool is the opposite of unguided cuttings

Similarities

The table saw, and chop saw are powerful and excellent power tools for cutting materials. Again, they do this will incredible precision. The abrasive chop saw can make 450 cuts as impressively as the table saw, and they are both easy to use and portable.

Difference

The purpose of these two tools is somewhat different. The table saw is mostly utilized for making a wide array of cuts, from angled to straight cuts, while the chop saw comes in handy in making straight cuts. On the other hand, the abrasive chop saw can make 450 cuts.

Chop saws are extremely powerful compared to table saws as they are used to cut even steel. Table saws are used for cutting wood only. Besides, the abrasive chop saw is relatively smaller than the table saw; thus, you can’t utilize it for larger projects. On the other hand, the TCT chop saw can cut through any material at high speed.

Which one should you choose?

Table saws are perfect for making countless cuts on wood, and they can easily handle a huge workload. So, if you are looking to make different cuts on a lot of wood, the table saw is a versatile option.

However, if you're looking to cut tough material and metal, you should go for the chop saw. It is a more powerful option, though it is more expensive than the table saw. Nonetheless, only the abrasive chop saw can make angled cuts.

Overall, the chop saw beats the table saw in terms of power and the number of materials it can cut. But you'll choose according to your needs and budget.

Why You Should Trust Us

At Woodworking Tool Guide, we know one size doesn't fit all! We cater to every woodworker, from beginner to pro, with insights and recommendations tailored to your skill level, project needs, and budget. We take the guesswork out of choosing the right tools, whether you're tackling your first crafting a masterpiece for the ages. So grab your chisel, join our community, and let's build something amazing together!

Woodworking Tool Guide wasn't just born, it sprouted from a seed of passion for the craft. What started as a joyful exploration blossomed into a trusted online haven for fellow enthusiasts like you. We pour our love into meticulously chosen review selections, meticulous hands-on testing, and lab-backed insights, all to empower you with reliable, comprehensive information you can build on. So, grab your tools, trust our guidance, and let's build something beautiful together!

Passion-Driven Expertise

Our journey started with a shared love for woodworking. The team behind the Woodworking Tool Guide is comprised of individuals who are not just writers but passionate woodworkers themselves. This shared enthusiasm ensures that our content is crafted with a deep understanding of the craft and an authentic appreciation for quality tools.

Top Tool Guides Online

Woodworking Tool Guide has rapidly ascended to become one of the premier online destinations for tool guidance. Our commitment to excellence and the accuracy of our information has positioned us as a reliable source for both beginners and seasoned woodworkers seeking trustworthy advice on the best tools for their projects.

User-Centric Approach

Our content caters to every woodworker, from rookies just starting out to seasoned pros tackling intricate projects. We tailor our insights and recommendations to your skill level, project needs, and budget, ensuring you find the perfect tools to match your unique woodworking journey. So step into your workshop, grab your tool belt, and let Woodworking Tool Guide be your trusted companion as you craft your masterpieces.

Continuous Support and Innovation

Woodworking is an ever-evolving craft, and so is our commitment to supporting you. We are dedicated to bringing you the latest information on woodworking tools, techniques, and trends. Our team is actively working to expand our content and bring you more valuable insights, ensuring that you stay well-informed in your woodworking adventure.

Hands-On Experience

Ditch the endless research rabbit hole! At Woodworking Tool Guide, we believe in actionable advice, not armchair analysis. We get our hands dirty, putting every tool through its paces in real-world woodworking scenarios. Whether it's the precision of a table saw, the versatility of a router, or the tactile satisfaction of a handplane, we test for performance, durability, and user-friendliness. No more sifting through dry specs – we deliver practical insights you can trust to transform your woodworking dreams into reality.

Woodworking Tool Guide isn't just a review site, it's your trusted companion on the sawdust-filled path to woodworking mastery. Our expert team, led by veteran David Jones, meticulously tests and explains tools in terms you understand. We cut through the jargon, bias, and confusion with real-world insights and honest evaluations. Join our passionate community, where decades of experience, cutting-edge knowledge, and shared love for the craft come together to guide you every step of the way. So grab your chisel, buckle up, and let's embark on this exciting woodworking adventure, together!