Power Tools

How To Set Up A Woodworking Shop

Nothing excites a woodworker more than a chance to set up a woodworking shop from scratch—and the idea of crafting a woodworking shop is appealing for multiple reasons. However, completing a project without a good woodworking shop and the necessary tools can be challenging.

Luckily, we understand this dilemma, and this is why we have posted this guide to help you quickly cross this hurdle and ultimately spark your plan to life. Following these few tips and considerations, you should have a perfectly functional woodworking shop in no time.

Here’s everything about how to set up a woodworking shop.

Start with proper woodworking space preparation

Creating an excellent working space is the first step to setting up a good woodworking shop. Knowing how much space you need helps you maximize your resources and build an appealing workstation. But how much space is enough for a woodworking shop? Truthfully, there's never enough.

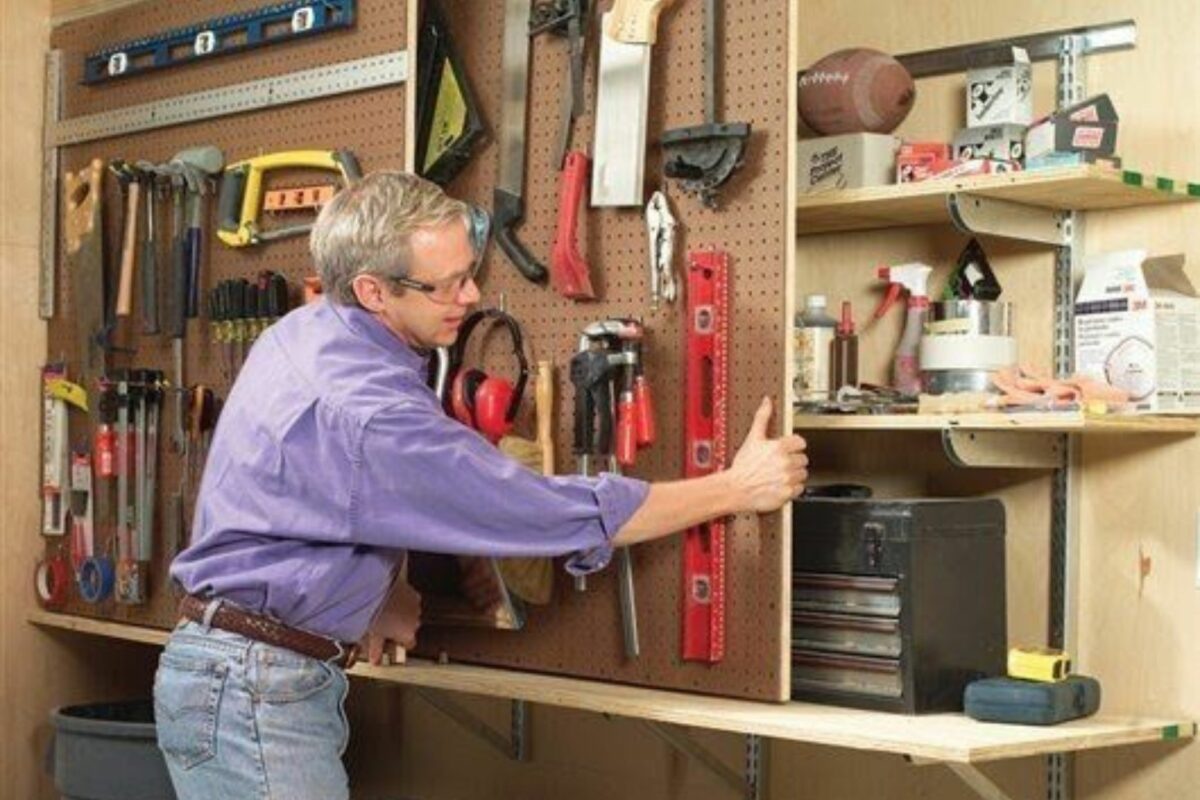

Ample space is fantastic, but the critical thing is efficiently using your space. The best way to maximize your woodworking space is to organize your room in a straight setting rather than the room's area. Also, think about where your tools will go where rather than how much space you have.

Most woodworking shop activities involve determining wood lengths like jointing and planning. This makes an L-shaped or more extended space might be a better fit compared to a square space—but both options are plentiful.

Planning your workshop space needs creative and efficient thinking. Linear tools like jointers and planers are good examples of woodworking tools whose overall length matters more than the width of their location.

Planers and jointers are linear tools –the width of their location isn't as important as the overall length of the workpiece. For instance, your benchtop planner could be 24'' wide, but when working on an 8’’ board, the linear space needed to do the job is only 16'. Miter saws are also linear-in width, not back-front, while table saws work in either direction.

Overall, woodworking workflow also matters. In your woodworking projects, the process generally starts from the wood storage to the milling, preparation, assembly, and finishing processes. Organize your woodwork shop to allow the smooth running of your operations.

Purchase the Basic Woodwork Equipment

Your workshop is only functional if it has the proper tools. Whether you are a DIYer or a Pro woodworker, your shop needs the right tools to operate. Furthermore, it would help if you had some marking devices. Purchase soft marking tools like markers and pencils and even an awl. Get a good marking gauge or even a mortising gauge.

Hand-held power tools like good woodworking jigsaws and circular saws are essential. Ratchet sets and a battery-powered drill isis also necessary to drive fasteners and make quick holes with zero effort.

If your plan involves equipping your woodworking shop with stationary gear, you should invest in a good miter or a quality beginner table saw. You can add an orbital sander too.

Buy a planner: planners are helpful in dimensioning stock, while a drill press is essential to allow super-accurate drilling.

Finally, ensure your woodworking shop is equipped with essential safety tools. Gloves, safety goggles, and ear protection equipment are necessary. Furthermore, to keep your woodworking shop clean & safe, ensure you have a shop vac to maintain a tidy working area.

Work on the necessary Mechanical considerations – Electricity, heating, cooling, etc.

Unless you plan to use hand tools 100% on your woodwork projects, you need to have electricity to power your woodworking gadgets. Moreover, it would help if you worked under suitable temperature conditions for optimal productivity. Home settings such as garages and basements usually feature outlets. Older buildings have relatively fewer outlets than modern homes.

After determining your layout, it's time to install electricity for your tools. If you want a small woodworking shop, properly using extension cords and several outlets may suffice.

Alternatively, larger shops call for professional electrical assistance to install extra lines. Once you invest in these units, know where your workshop tools will go to direct outlets and new cords, where necessary, effectively. Also, remember to add a few light fixtures on your ceiling for ample lighting.

When installing electricity, ensure you understand your workshop tools' necessary amperage/voltage. Ideally, most hand-held power gadgets comprise 110- and 220-volt outlets. Also, larger devices with low horsepower motors often utilize these standard power outlets. You can always consult a professional electrician to make an accurate determination and make your work easier.

Your preferred cooling and heating need usually depend on your workshop’s structure and geographical location. Therefore, consider using fans since they regulate temperature and help eradicate the fumes associated with woodworking processes.

Standard garages feature at least one window for ventilation purposes, although you can also raise your workshop door several inches up. Ideally, having a well-placed window unit or floor fan can quickly exhaust dust and exhaust fumes from a small workshop.

For optimal space usage, consider dressing in layers and space heaters for cold periods and store temperature-sensitive finishes and glues in relatively warmer locations. If you have a basement shop, consult a professional HVAC personnel to identify if your home cooling/heating system is well-equipped to cater to square footage with some extra vents in the workspace.

Adequate Illumination

Proper lighting and illumination are essential for a functional woodworking shop. Typically, you should invest in generating light from multiple sources instead of a single bulb or lamp since the latter will cast shadows and conceal imperfections on your workpiece's surface. Also, more than one light source will be needed to illuminate your workshop area, adequately hindering proper operation.

The best light fixtures to consider are LED over fluorescents. Why? LED fixtures don’t flicker like standard fluorescents, last longer, and are unaffected by cold weather. While LEDs are costlier, they offer more value for your money ultimately.

Once you hang the first LED fixture, additional ones can be interlinked in a continuous line of full-coverage, bright lighting installed under a single power outlet. There are numerous model installations; hence you need to find the appropriate one for your woodwork shop by comparing and determining the best package.

Finally, one often overlooked light aspect is the woodworking shop's appearance. Basements and garages can usually be dabbed with wood studs, bare drywall, concrete walls, and plywood sheeting that swallow light remarkably. You'll be surprised at how much brighter your space can be by applying a white paint coat to your walls and ceiling.

Why You Should Trust Us

At Woodworking Tool Guide, we know one size doesn't fit all! We cater to every woodworker, from beginner to pro, with insights and recommendations tailored to your skill level, project needs, and budget. We take the guesswork out of choosing the right tools, whether you're tackling your first crafting a masterpiece for the ages. So grab your chisel, join our community, and let's build something amazing together!

Woodworking Tool Guide wasn't just born, it sprouted from a seed of passion for the craft. What started as a joyful exploration blossomed into a trusted online haven for fellow enthusiasts like you. We pour our love into meticulously chosen review selections, meticulous hands-on testing, and lab-backed insights, all to empower you with reliable, comprehensive information you can build on. So, grab your tools, trust our guidance, and let's build something beautiful together!

Passion-Driven Expertise

Our journey started with a shared love for woodworking. The team behind the Woodworking Tool Guide is comprised of individuals who are not just writers but passionate woodworkers themselves. This shared enthusiasm ensures that our content is crafted with a deep understanding of the craft and an authentic appreciation for quality tools.

Top Tool Guides Online

Woodworking Tool Guide has rapidly ascended to become one of the premier online destinations for tool guidance. Our commitment to excellence and the accuracy of our information has positioned us as a reliable source for both beginners and seasoned woodworkers seeking trustworthy advice on the best tools for their projects.

User-Centric Approach

Our content caters to every woodworker, from rookies just starting out to seasoned pros tackling intricate projects. We tailor our insights and recommendations to your skill level, project needs, and budget, ensuring you find the perfect tools to match your unique woodworking journey. So step into your workshop, grab your tool belt, and let Woodworking Tool Guide be your trusted companion as you craft your masterpieces.

Continuous Support and Innovation

Woodworking is an ever-evolving craft, and so is our commitment to supporting you. We are dedicated to bringing you the latest information on woodworking tools, techniques, and trends. Our team is actively working to expand our content and bring you more valuable insights, ensuring that you stay well-informed in your woodworking adventure.

Hands-On Experience

Ditch the endless research rabbit hole! At Woodworking Tool Guide, we believe in actionable advice, not armchair analysis. We get our hands dirty, putting every tool through its paces in real-world woodworking scenarios. Whether it's the precision of a table saw, the versatility of a router, or the tactile satisfaction of a handplane, we test for performance, durability, and user-friendliness. No more sifting through dry specs – we deliver practical insights you can trust to transform your woodworking dreams into reality.

Woodworking Tool Guide isn't just a review site, it's your trusted companion on the sawdust-filled path to woodworking mastery. Our expert team, led by veteran David Jones, meticulously tests and explains tools in terms you understand. We cut through the jargon, bias, and confusion with real-world insights and honest evaluations. Join our passionate community, where decades of experience, cutting-edge knowledge, and shared love for the craft come together to guide you every step of the way. So grab your chisel, buckle up, and let's embark on this exciting woodworking adventure, together!

Final Word

Establishing a functional woodworking shop may be among the most captivating activities for any pro or aspiring woodworker. However, it is not a one-time endeavor. Build your workshop space gradually as you progress in your woodwork venture. No matter how it turns out, we guarantee you will modify your area setting as you get more equipment, workloads, and complex tasks. In the end, remember to leave yourself with all the items outlined here at a time.

Pick and determine what to work on, what's necessary to start operations, and what works with your budget. It will soon be that you've created the perfect woodworking shop that excites and inspires you.

Good luck!